Manufacturers of machine parts such as springs and wire forms promise quality designs and advanced engineering services. It is important that you choose the right custom spring manufacturer in Oklahoma or other locations for this particular type of products and services.

Many of the good things experienced by the machinery industry are rarely blatantly attributed to parts manufacturing businesses, but there is an easy explanation for this. It’s because it is such a common thing that happens in the background that acknowledging it like this seems a bit absurd. However, for the sake of this list, we must state that any machine design will not exist without its components. Every machine is only as successful as its individual parts.

It is important that we work with parts manufacturing companies that do not lack in component design aptitude and in having sufficient engineering technology to support it. After all, our company’s image and reputation will rest on the quality and timeliness of our chosen manufacturer’s delivery.

Here are some things to consider when choosing a custom parts manufacturer:

Quality

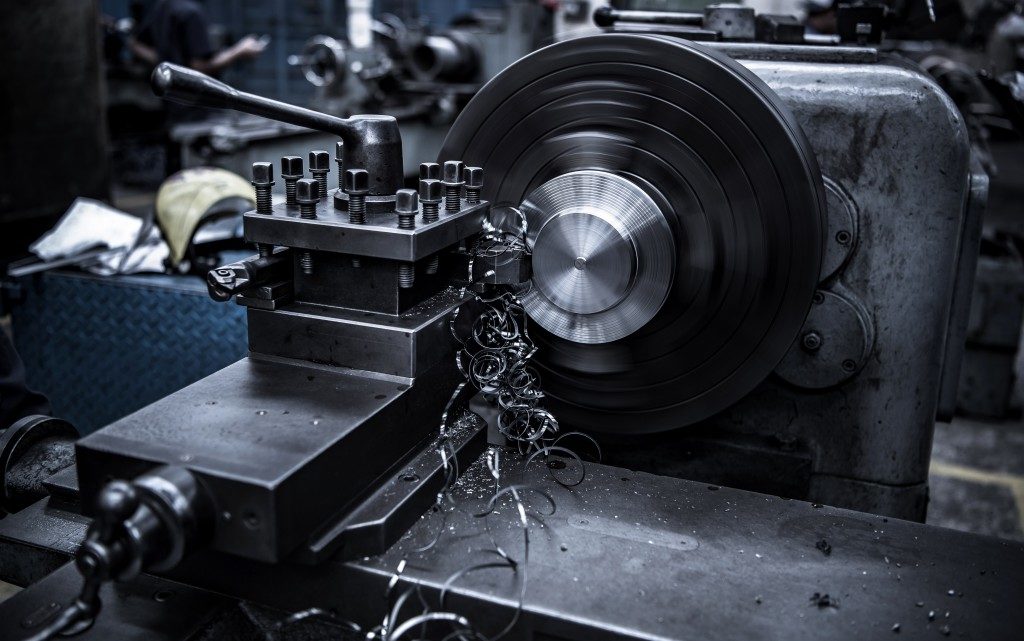

A single component’s design and its subsequent execution will ultimately define the product that it’s going to be a part of. A competent parts manufacturer is integral to the realization of a desired final assembly. The smallest of oversights on the part of a reckless parts manufacturer can affect the finished product’s overall quality – visual, tactile, and most importantly, function-wise. A seemingly small mistake both during the design and the parts building process can make or break the final product.

The manufacturer must have enough relevant experience to know for sure the most ideal options for a given part’s material, finishing, and manufacturing techniques.

Time Efficiency

The competence of a parts manufacturer extends to their ability to finish a particular order with the correct specifications within a required time frame. Studies have been made about how even just a day of delay can cause drastic cost deviations that can be detrimental to business operations. Not only do these incidents damage predetermined ideal product results, but it also negatively impacts business relationships and morale. In some cases, a delay in the delivery of even just one custom part can derail a company’s whole production process.

Moreover, if the manufacturer is also designing parts for our product, their aptitude in this field must also be considered. An unqualified parts manufacturer can come up with a production design that will serve your specified desired purpose, yes, but it might also likely be so complex that it renders your building timeframe unnecessarily extended when you could have chosen to work with a better alternative.

Rapport

Building an effective and open communication line with a parts manufacturing company is important because regular correspondence will be a necessity. Through the establishment of good rapport early on, any mistakes in the design and production of the parts can be detected and corrected early. This also applies to changes or adjustments that come up or to suddenly required additions throughout the process.

Because of the huge amounts of time, money, and effort that we need to invest in the business of finding quality designers and suppliers of machine parts, it is important that we make the right choice. Companies that are confident in design and workmanship capacity, backed by experience and testimonials, can greatly help us with our industrial and mechanical parts needs.